One of the benefits of tape is that you can determine the stability of the bond in advance. Is a lifetime love? Or do you play at the scene? Or is it temporary or intermittent? We will take care of it for you.

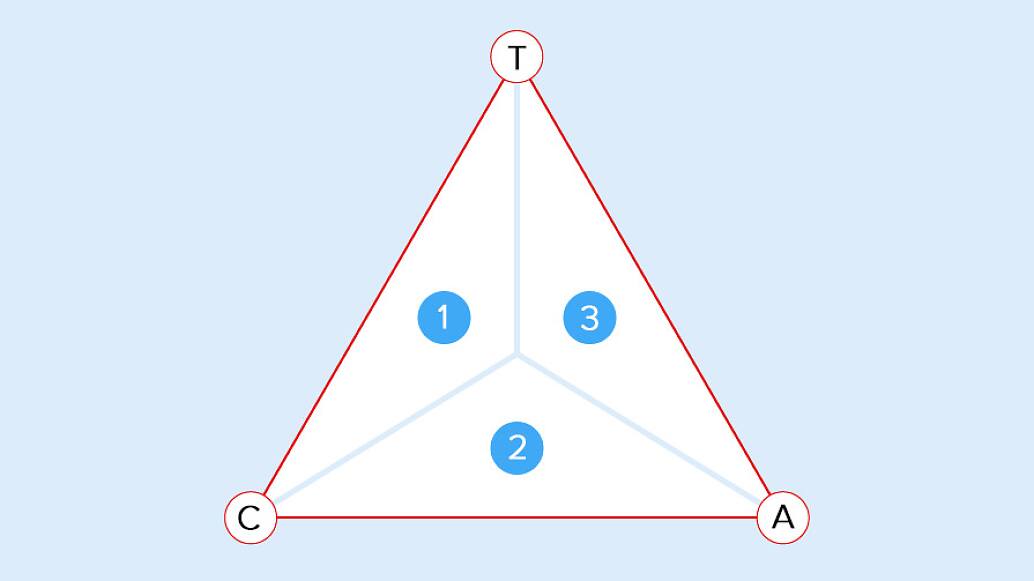

Let’s start with the basics: the three forces involved with adhesives. Cohesion, or internal tack, determines the ability of an adhesive to resist tearing. Adhesion, the tackiness of an adhesive, refers to the ability to adhere to non-adhesive objects. Initial adhesion, that is, the ability of the adhesive to adhere to the surface in a very short time. So how do I set these three parameters to get the tape that meets my requirements?

The balance between initial adhesion, cohesion and adhesion determines the application area

Temporary and reversible bonding

The initial adhesion and cohesion are customized according to the application conditions. Adhesion is a secondary factor. In many applications, the balance between initial adhesion and cohesion is important. To ensure that the tape can immediately adhere to the surface, initial adhesion is essential. If the product can be removed without leaving a trace, a high cohesion is required, that is, the internal firmness of the adhesive. For many reversible applications, some parameters are more important than high adhesion, such as high initial adhesion values (peel strength).

Tapes with these characteristics are used for a wide range of applications, such as pre-installation during assembly, masking of sensitive surfaces when painting, protection of newly sprayed car paint during transportation, and assembly of printing plates.

Permanent bonding

If objects are to be permanently bonded, adhesion and cohesion are equally important and need to be adjusted for specific applications. In permanent bonding, initial adhesion is a secondary factor. The greatest feature of this type of adhesive is that the relationship between cohesion and adhesion must be suitable for a particular application. The focus is on the bonding properties. Initial adhesion, the ability to adhere at the moment of contact, is usually a secondary factor.

Application areas include the assembly of curtain wall components or furniture panels, automotive decorative parts, profiles and logos, camera lenses for mobile phones, etc., as well as automotive wiring harness bundling and protection. All of these applications require permanent bonding and secure fixing, and must have anti-aging properties and a long service life.

Fast bonding

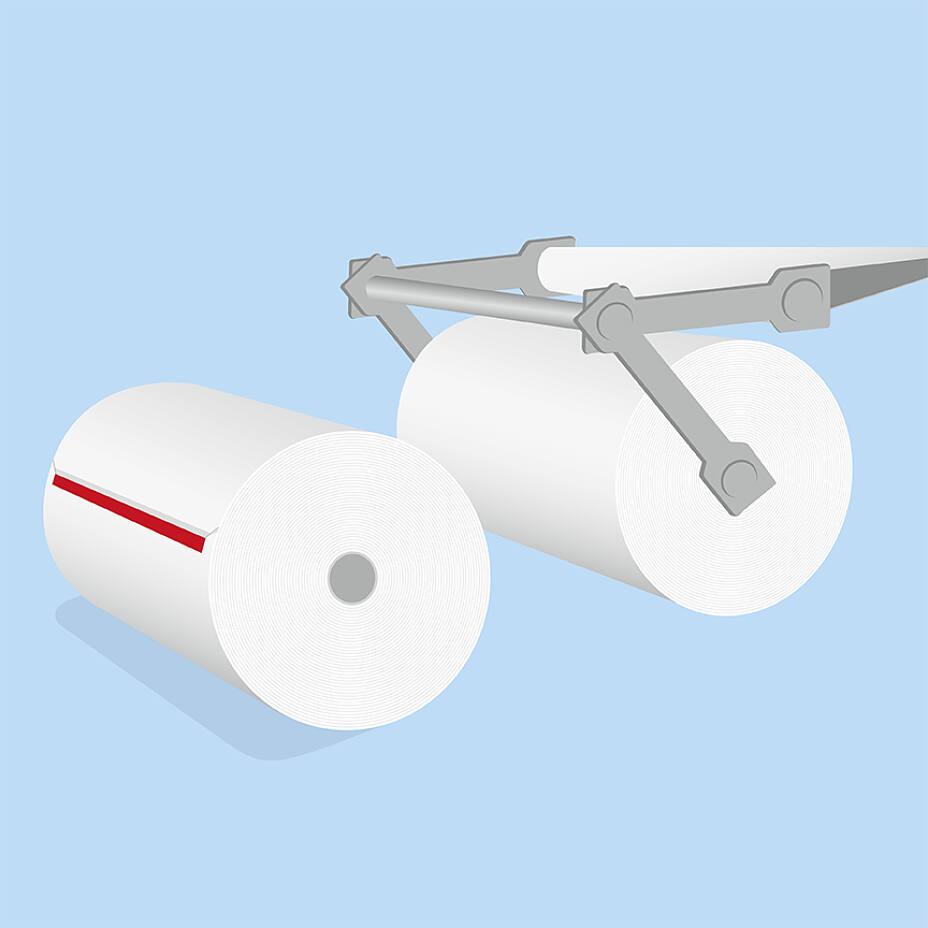

Sometimes the speed of bonding must be fast. At this time, the relationship between the initial adhesion and the adhesion is very important, and both need to be adjusted according to the specific application. Cohesion then becomes a secondary factor. For adhesives in this field, it is important that they are able to stick firmly instantly. In other words, both the initial adhesion and the adhesion are relatively high. Since the adhesive usually does not need to transmit a large load, and it does not need to leave a trace after it is removed, the cohesion is now at the second line.

Fly-connect is a good example. In the paper and newspaper printing industry, flying splice tape is responsible for joining the end of the previous roll of paper with the beginning of the next roll of paper. The bonding process must be completed while the machine is running at full speed. The end of the previous volume is connected to the beginning of the next volume. The contact, although short, must be sufficient to produce a strong bond. Film screen printing of packaging materials is a similar process.

Shenzhen World Packing Industrial Ltd

Stretch Film & Packing Tape Specialist , Top China manufacturer

Contact us & let’s make Win-Win business, always stable quality stretch film, save you time & cost. : )